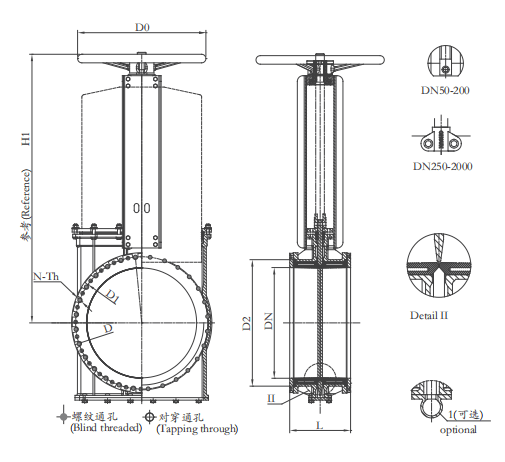

JQWL Series Warman Slurry Knife Gate Valve

JQWL Series Bi-directional Self-sealing Warman Slurry Knife Gate Valve/Medium Pressure

Product Description: JQWL Series Self-sealing knife gate valve is to use two rubber seats on the clip pressed the knife a sealing effect. When the knife is fully open, the two-seat seals combined together tightly, the pipeline pressure will make sealing better, while the valve is closed, the gate can be arbitrarily removed convenient maintenance, Sleeve on both sides of seat, Full protection of the valve body, Extend valve life

Model: JQWLZ53X

Working Pressure: DN80-DN800 20bar, DN900-DN1000 16bar

Type: Lug

Design Standard: MSS SP-81

Flange Standard: DIN PN10,PN16,150LB ,JIS 10K,TABLE E/D

Face to Face: MSS SP-81

Testing Standard: API-598

Operation: handwheel, electric, pneumatic, hydraulic, sprocket, electro-hydraulic, gear

Main material: GGG40, WCB

Wedge material: SS316L,SS304

Sealing material: NR, EPDM

Packing: Rubber

Applicable medium: Applicable to the slurry, urban sewage treatment, powder, paper, chemicals, and other fields

DIN2632 PN10

| DN | L | D | D1 | D2 | D0 | N-Th | d | H1 |

| 50 | 172 | 165 | 125 | 99 | 180 | 4-M16 | Ø18 | 260 |

| 65 | 172 | 185 | 145 | 118 | 200 | 4-M16 | Ø18 | 292 |

| 80 | 172 | 200 | 160 | 132 | 200 | 8-M16 | Ø18 | 320 |

| 100 | 172 | 220 | 180 | 156 | 240 | 8-M16 | Ø18 | 358 |

| 125 | 174 | 250 | 210 | 184 | 260 | 8-M16 | Ø18 | 395 |

| 150 | 174 | 285 | 240 | 211 | 280 | 8-M20 | Ø23 | 450 |

| 200 | 180 | 340 | 295 | 266 | 300 | 8-M20 | Ø23 | 532 |

| 250 | 220 | 395 | 350 | 319 | 320 | 12-M20 | Ø23 | 670 |

| 300 | 255 | 445 | 400 | 370 | 350 | 12-M20 | Ø23 | 758 |

| 350 | 255 | 505 | 460 | 429 | 400 | 16-M20 | Ø23 | 857 |

| 400 | 281 | 565 | 515 | 480 | 450 | 16-M24 | Ø27 | 946 |

| 450 | 305 | 615 | 565 | 530 | 500 | 20-M24 | Ø27 | 1023 |

| 500 | 350 | 670 | 620 | 582 | 500 | 20-M24 | Ø27 | Gear |

| 600 | 369 | 780 | 725 | 682 | – | 20-M27 | Ø30 | Gear |

| 700 | 372 | 895 | 840 | 794 | – | 24-M27 | Ø30 | Gear |

| 800 | 405 | 1015 | 950 | 901 | – | 24-M30 | Ø33 | Gear |

| 900 | 480 | 1115 | 1050 | 1001 | – | 28-M30 | Ø33 | Gear |

| 1000 | 535 | 1230 | 1160 | 1112 | – | 28-M33 | Ø36 | Gear |

ANSI 150LB

| DN | L | D | D1 | D2 | D0 | N-Th | d | H1 |

| 2″ | 172 | 152 | 121 | 92 | 180 | 4-5/8″ | Ø19 | 260 |

| 2-1/2″ | 172 | 178 | 140 | 105 | 200 | 4-5/8″ | Ø19 | 292 |

| 3″ | 172 | 191 | 153 | 127 | 200 | 4-5/8″ | Ø19 | 320 |

| 4″ | 172 | 229 | 191 | 157 | 240 | 8-5/8″ | Ø19 | 358 |

| 5″ | 174 | 254 | 216 | 186 | 260 | 8-3/4″ | Ø22 | 395 |

| 6″ | 174 | 279 | 242 | 216 | 280 | 8-3/4″ | Ø22 | 450 |

| 8″ | 180 | 343 | 299 | 270 | 300 | 8-3/4″ | Ø22 | 532 |

| 10″ | 220 | 406 | 362 | 324 | 320 | 12-7/8″ | Ø25 | 670 |

| 12″ | 255 | 483 | 432 | 381 | 350 | 12-7/8″ | Ø25 | 758 |

| 14″ | 255 | 533 | 476 | 413 | 400 | 12-1″ | Ø29 | 857 |

| 16″ | 281 | 597 | 540 | 470 | 450 | 16-1″ | Ø29 | 946 |

| 18″ | 305 | 635 | 578 | 533 | 500 | 16-1 1/8″ | Ø32 | 1023 |

| 20″ | 350 | 699 | 635 | 584 | 500 | 20-1 1/8″ | Ø32 | Gear |

| 24″ | 369 | 813 | 750 | 691 | – | 20-1 1/4″ | Ø35 | Gear |

| 28″ | 372 | 927 | 864 | 800 | – | 28-1 1/4″ | Ø35 | Gear |

| 32″ | 405 | 1060 | 978 | 914 | – | 28-1 1/2″ | Ø41 | Gear |

| 36″ | 480 | 1170 | 1086 | 1022 | – | 32-1 1/2″ | Ø41 | Gear |

| 40″ | 535 | 1290 | 1200 | 1124 | – | 36-1 1/2″ | Ø41 | Gear |