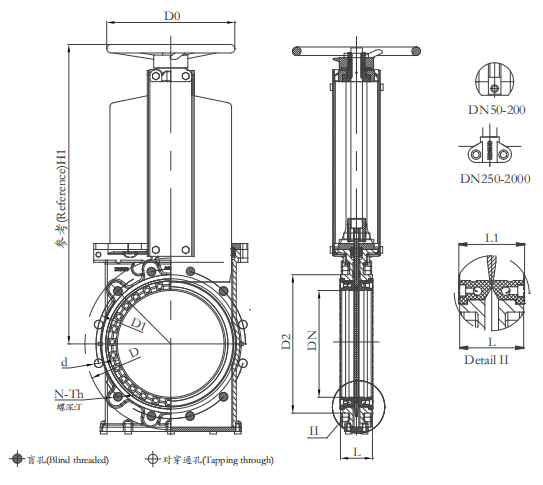

JQW Series Knife Slurry Valve

JQW Series Bi-directional Self-sealing Knife Slurry Valve

Product Description: JQW Series Self-sealing knife gate valve is to use two rubber seats on the clip pressed the knife a sealing effect. When the knife is fully open, the two-seat seals combined together tightly, the pipeline pressure will make sealing better, while the valve is closed, the gate can be arbitrarily removed convenient maintenance, no need to remove the entire valve repair and does not affect the normal operation of the pipeline. The main characteristics of the valve bore full rubber seal seat, has a strong anti-wear property and all-pass run off continuity. Suitable for use on those requirements valve wear mining.

Model: JQWZ73X

Working Pressure: DN50-DN100 16bar, DN125-DN200 10bar, DN250-DN400 7bar, DN450-DN500 5Bar,DN600-DN700 3bar, DN800 2bar

Type: Wafer

Design Standard: MSS SP-81

Flange Standard: DIN PN10,PN16,150LB ,JIS 10K,TABLE E/D

Face to Face: MSS SP-81

Testing Standard: API-598

Operation: handwheel, electric, pneumatic, hydraulic, sprocket, electro-hydraulic, gear

Main material: GGG40

Wedge material: SS316L,SS304

Sealing material: NBR, FKM, PU

Packing: Rubber

Applicable medium: Applicable to the slurry, urban sewage treatment, sugar, powder, paper, medicine, chemicals, food, and other fields

PN10

| DN | L | D | D1 | D2 | D0 | N-Th | d | H1 |

| 50 | 53 | 165 | 125 | 99 | 180 | 4-M16 | Ø18 | 260 |

| 65 | 53 | 185 | 145 | 118 | 200 | 4-M16 | Ø18 | 292 |

| 80 | 56.5 | 200 | 160 | 132 | 200 | 8-M16 | Ø18 | 320 |

| 100 | 56.5 | 220 | 180 | 156 | 240 | 8-M16 | Ø18 | 358 |

| 125 | 63 | 250 | 210 | 184 | 260 | 8-M16 | Ø18 | 395 |

| 150 | 62 | 285 | 240 | 211 | 280 | 8-M20 | Ø23 | 450 |

| 200 | 76.5 | 340 | 295 | 266 | 300 | 8-M20 | Ø23 | 532 |

| 250 | 75.5 | 395 | 350 | 319 | 320 | 12-M20 | Ø23 | 670 |

| 300 | 84 | 445 | 400 | 370 | 350 | 12-M20 | Ø23 | 758 |

| 350 | 84 | 505 | 460 | 429 | 400 | 16-M20 | Ø23 | 857 |

| 400 | 99 | 565 | 515 | 480 | 450 | 16-M24 | Ø27 | 946 |

| 450 | 99 | 615 | 565 | 530 | 500 | 20-M24 | Ø27 | 1023 |

| 500 | 129 | 670 | 620 | 582 | 500 | 20-M24 | Ø27 | Gear |

| 550 | 129 | 725 | 680 | 638 | – | 20-M27 | Ø30 | Gear |

| 600 | 129 | 780 | 725 | 682 | – | 20-M27 | Ø30 | Gear |

| 700 | 142 | 895 | 840 | 794 | – | 24-M27 | Ø30 | Gear |

| 800 | 142 | 1015 | 950 | 901 | – | 24-M30 | Ø33 | Gear |

ANSI 150LB

| DN | L | D | D1 | D2 | D0 | N-Th | d | H1 |

| 2″ | 53 | 152 | 121 | 92 | 180 | 4-5/8″ | Ø19 | 260 |

| 2-1/2″ | 53 | 178 | 140 | 105 | 200 | 4-5/8″ | Ø19 | 292 |

| 3″ | 56.5 | 191 | 153 | 127 | 200 | 4-5/8″ | Ø19 | 320 |

| 4″ | 56.5 | 229 | 191 | 157 | 240 | 8-5/8″ | Ø19 | 358 |

| 5″ | 63 | 254 | 216 | 186 | 260 | 8-3/4″ | Ø22 | 395 |

| 6″ | 62 | 279 | 242 | 216 | 280 | 8-3/4″ | Ø22 | 450 |

| 8″ | 76.5 | 343 | 299 | 270 | 300 | 8-3/4″ | Ø22 | 532 |

| 10″ | 75.5 | 406 | 362 | 324 | 320 | 12-7/8″ | Ø25 | 670 |

| 12″ | 84 | 483 | 432 | 381 | 350 | 12-7/8″ | Ø25 | 758 |

| 14″ | 84 | 533 | 476 | 413 | 400 | 12-1″ | Ø29 | 857 |

| 16″ | 99 | 597 | 540 | 470 | 450 | 16-1″ | Ø29 | 946 |

| 18″ | 99 | 635 | 578 | 533 | 500 | 16-1 1/8″ | Ø32 | 1023 |

| 20″ | 129 | 699 | 635 | 584 | 500 | 20-1 1/8″ | Ø32 | Gear |

| 22″ | 129 | 750 | 692 | 641 | – | 20-1 1/4″ | Ø35 | Gear |

| 24″ | 129 | 813 | 750 | 691 | – | 20-1 1/4″ | Ø35 | Gear |

| 28″ | 142 | 927 | 864 | 800 | – | 28-1 1/4″ | Ø35 | Gear |

| 32″ | 142 | 1060 | 978 | 914 | – | 28-1 1/2″ | Ø41 | Gear |

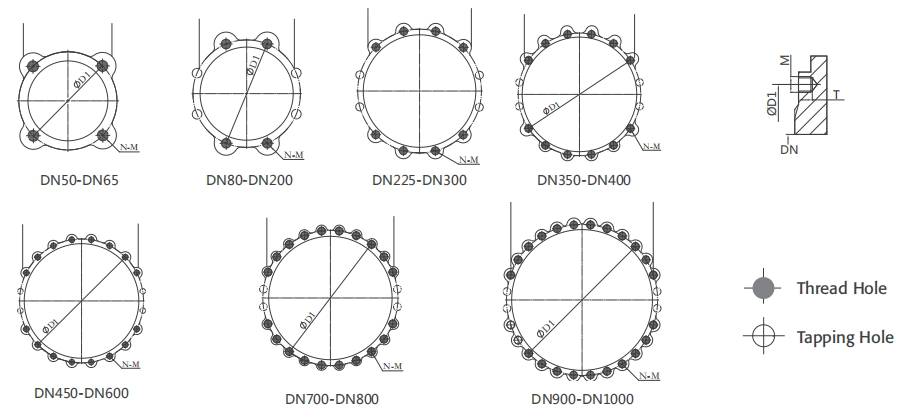

PN10 Threaded hole and Tapping hole

| DN | D1 | N | M | T | Thread Hole | Tapping Hole |

| 50 | 125 | 4 | M16 | 13 | 2 | 2 |

| 65 | 145 | 4 | M16 | 13 | 2 | 2 |

| 80 | 160 | 8 | M16 | 13 | 2 | 6 |

| 100 | 180 | 8 | M16 | 13 | 2 | 6 |

| 125 | 210 | 8 | M16 | 16 | 2 | 6 |

| 150 | 240 | 8 | M16 | 16 | 2 | 6 |

| 200 | 295 | 8 | M20 | 20 | 2 | 6 |

| 225 | 310 | 12 | M20 | 20 | 4 | 8 |

| 250 | 350 | 12 | M20 | 20 | 4 | 8 |

| 300 | 400 | 12 | M20 | 20 | 4 | 8 |

| 350 | 460 | 16 | M20 | 20 | 8 | 8 |

| 400 | 515 | 16 | M24 | 24 | 8 | 8 |

| 450 | 565 | 20 | M24 | 24 | 16 | 4 |

| 500 | 620 | 20 | M24 | 24 | 16 | 4 |

| 550 | 680 | 20 | M27 | 24 | 16 | 4 |

| 600 | 725 | 20 | M27 | 27 | 16 | 4 |

| 700 | 840 | 24 | M27 | 27 | 20 | 4 |

| 800 | 950 | 24 | M30 | 30 | 20 | 4 |

| 900 | 1050 | 28 | M30 | 30 | 24 | 4 |

| 1000 | 1160 | 28 | M33 | 33 | 24 | 4 |

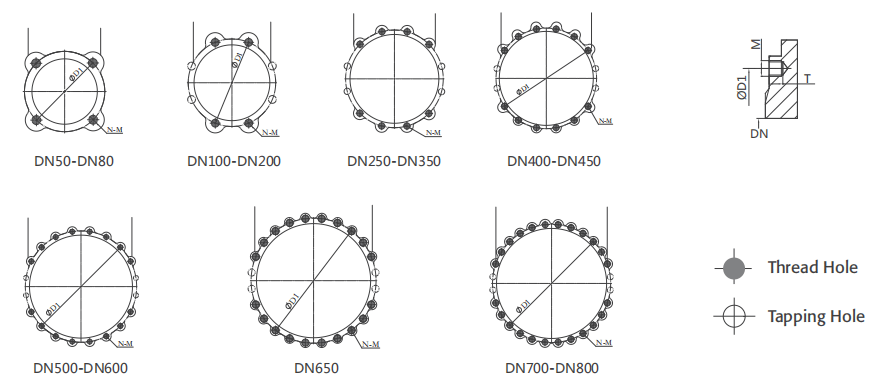

150LB Threaded hole and Tapping hole

| DN | D1 | N | M | T | Thread Hole | Tapping Hole |

| 2″(DN50) | 121 | 4 | M5/8-11 | 13 | 4 | 0 |

| 2-1/2″(DN65) | 140 | 4 | M5/8-11 | 13 | 4 | 0 |

| 3″(DN80) | 153 | 4 | M5/8-11 | 13 | 4 | 0 |

| 4″(DN100) | 191 | 8 | M5/8-11 | 13 | 4 | 4 |

| 5″(DN125) | 216 | 8 | M3/4-10 | 16 | 4 | 4 |

| 6″(DN150) | 242 | 8 | M3/4-10 | 16 | 4 | 4 |

| 8″(DN200) | 299 | 8 | M3/4-10 | 20 | 4 | 4 |

| 10″(DN250) | 362 | 12 | M7/8-9 | 20 | 8 | 4 |

| 12″(DN300) | 432 | 12 | M7/8-9 | 20 | 8 | 4 |

| 14″(DN350) | 476 | 12 | M1-8 | 20 | 8 | 4 |

| 16″(DN400) | 540 | 16 | M1-8 | 24 | 12 | 4 |

| 18″(DN450) | 578 | 16 | M1 1/8-7 | 24 | 12 | 4 |

| 20″(DN500) | 635 | 20 | M1 1/8-7 | 24 | 16 | 4 |

| 22″(DN550) | 692 | 20 | M1 1/4-7 | 24 | 16 | 4 |

| 24″(DN600) | 750 | 20 | M1 1/4-7 | 27 | 16 | 4 |

| 26″(DN650) | 806 | 24 | M1 1/4-7 | 27 | 20 | 4 |

| 28″(DN700) | 864 | 28 | M1 1/4-7 | 27 | 24 | 4 |

| 30″(DN750) | 914 | 28 | M1 1/4-7 | 27 | 24 | 4 |

| 32″(DN800) | 978 | 28 | M1 1/2-6 | 30 | 24 | 4 |