JQC Series Knife Gate Valve

JQC Series Bi-directional Seal Knife Gate Valve/Disc Through the type

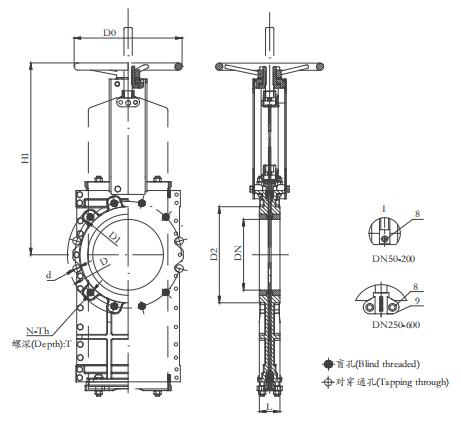

Product Description: JQC Series No groove bi-directional seal knife gate valve, cast iron body with the overall structure knife gate valve, including valve body, gate, and U-shaped flexible seal at the bottom of the body with grooves. When the valve is closed, the bottom of the gate edge contact with the seal and then compress the seal into the groove in the body and sealed gate realization; when the gate opens, the separate gate from the bottom edge of the seal, the seal will bounce to the same level as the groove, which will prevent the media sediment accumulated in the body cavity of the groove, no clogging, no residue, pipe easy to clean, so as to effectively improve the sealing effect knife gate valve to prevent leakage when the valve is closed.

Model: JQCZ73X

Working Pressure: DN50-DN100 16bar,DN125-DN200 10bar ,DN250-DN300 12bar ,DN350-DN400 10bar

Type: Wafer

Design Standard: MSS SP-81

Flange Standard: DIN PN10,PN16,150LB ,JIS 10K,TABLE E/D

Face to Face: MSS SP-81

Testing Standard: API-598

Operation: handwheel, electric, pneumatic, hydraulic, sprocket, electro-hydraulic, gear box

Main material:WCB,CF8M,CF8,F55,F53,2205,SS310,CF3M, CF3

Knife material: SS316L,SS304

Sealing material: EPDM,NBR,FKM,Metal

Packing: Aramid fiber,high-water-based rubber packing graphite

Applicable medium: Applicable for coal in power plant, sewage treatment, food, paper making, medicine, petroleum and chemical industry, water, oil, steam, connecting or cutting grout, gold powder, ores, slag, coal, pulp, wood pulp, tailings, fibers, dust, chemicals, sewage treatment, sedimentation tanks, asphalt, bunker export, cereals, slaughter plant waste, and other media.

DIN2632 PN10

| DN | L | D | D1 | D2 | D0 | N-Th | d | H1 |

| 50 | 48 | 165 | 125 | 99 | 180 | 4-M16 | Ø18 | 260 |

| 65 | 48 | 485 | 145 | 118 | 200 | 4-M16 | Ø18 | 292 |

| 80 | 51 | 200 | 160 | 132 | 200 | 8-M16 | Ø18 | 320 |

| 100 | 51 | 220 | 180 | 156 | 240 | 8-M16 | Ø18 | 358 |

| 125 | 57 | 250 | 210 | 184 | 260 | 8-M16 | Ø18 | 395 |

| 150 | 57 | 285 | 240 | 211 | 280 | 8-M20 | Ø23 | 450 |

| 200 | 70 | 340 | 295 | 266 | 300 | 8-M20 | Ø23 | 532 |

| 250 | 70 | 395 | 350 | 319 | 320 | 12-M20 | Ø23 | 670 |

| 300 | 76 | 445 | 400 | 370 | 350 | 12-M20 | Ø23 | 758 |

| 350 | 76 | 505 | 460 | 429 | 400 | 16-M20 | Ø23 | 857 |

| 400 | 89 | 565 | 515 | 480 | 450 | 16-M24 | Ø27 | 946 |

| 450 | 89 | 615 | 565 | 530 | 500 | 20-M24 | Ø27 | 1023 |

| 500 | 114 | 670 | 620 | 582 | 500 | 20-M24 | Ø27 | Gear |

ANSI 150LB

| DN | L | D | D1 | D2 | D0 | N-Th | d | H1 |

| 2″ | 48 | 152 | 121 | 92 | 180 | 4-5/8″ | Ø19 | 260 |

| 2-1/2″ | 48 | 178 | 140 | 105 | 200 | 4-5/8″ | Ø19 | 292 |

| 3″ | 51 | 191 | 153 | 127 | 200 | 4-5/8″ | Ø19 | 320 |

| 4″ | 51 | 229 | 191 | 157 | 240 | 8-5/8″ | Ø19 | 358 |

| 5″ | 57 | 254 | 216 | 186 | 260 | 8-3/4″ | Ø22 | 395 |

| 6″ | 57 | 279 | 242 | 216 | 280 | 8-3/4″ | Ø22 | 450 |

| 8″ | 70 | 343 | 299 | 270 | 300 | 8-3/4″ | Ø22 | 532 |

| 10″ | 70 | 406 | 362 | 324 | 320 | 12-7/8″ | Ø25 | 670 |

| 12″ | 76 | 483 | 432 | 381 | 350 | 12-7/8″ | Ø25 | 758 |

| 14″ | 76 | 533 | 476 | 413 | 400 | 12-1″ | Ø29 | 857 |

| 16″ | 89 | 597 | 540 | 470 | 450 | 16-1″ | Ø29 | 946 |

| 18″ | 89 | 635 | 578 | 533 | 500 | 16-1 1/8″ | Ø32 | 1023 |

| 20″ | 114 | 699 | 635 | 584 | 500 | 20-1 1/8″ | Ø32 | Gear |

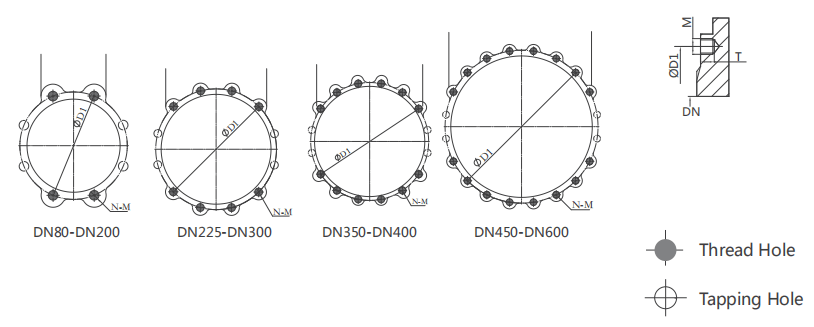

PN10 Threaded hole and Tapping hole

| DN | D1 | N | M | T | Thread Hole | Tapping Hole |

| 80 | 160 | 8 | M16 | 13 | 4 | 4 |

| 100 | 180 | 8 | M16 | 13 | 4 | 4 |

| 125 | 210 | 8 | M16 | 16 | 4 | 4 |

| 150 | 240 | 8 | M16 | 16 | 4 | 4 |

| 200 | 295 | 8 | M20 | 20 | 4 | 4 |

| 225 | 310 | 12 | M20 | 20 | 8 | 4 |

| 250 | 350 | 12 | M20 | 20 | 8 | 4 |

| 300 | 400 | 12 | M20 | 20 | 8 | 4 |

| 350 | 460 | 16 | M20 | 20 | 12 | 4 |

| 400 | 515 | 16 | M24 | 24 | 12 | 4 |

| 450 | 565 | 20 | M24 | 24 | 16 | 4 |

| 500 | 620 | 20 | M24 | 24 | 16 | 4 |

| 550 | 680 | 20 | M27 | 24 | 16 | 4 |

| 600 | 725 | 20 | M27 | 27 | 16 | 4 |

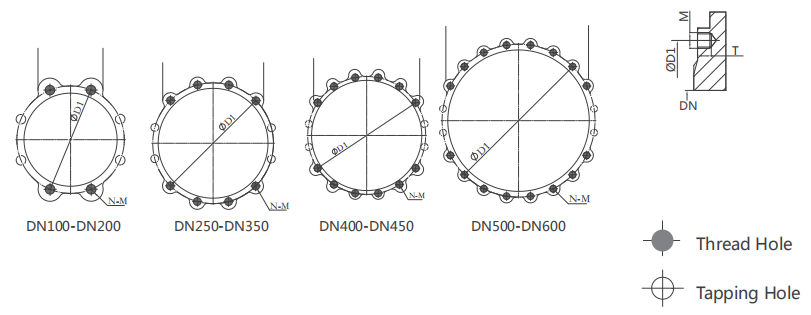

150LB Threaded hole and Tapping hole

| DN | D1 | N | M | T | Thread Hole | Tapping Hole |

| 4″(DN100) | 191 | 8 | M5/8-11 | 12 | 4 | 4 |

| 5″(DN125) | 216 | 8 | M3/4-10 | 12 | 4 | 4 |

| 6″(DN150) | 242 | 8 | M3/4-10 | 14 | 4 | 4 |

| 8″(DN200) | 299 | 8 | M3/4-10 | 16 | 4 | 4 |

| 10″(DN250) | 362 | 12 | M7/8-9 | 16 | 8 | 4 |

| 12″(DN300) | 432 | 12 | M7/8-9 | 16 | 8 | 4 |

| 14″(DN350) | 476 | 12 | M1-8 | 18 | 8 | 4 |

| 16″(DN400) | 540 | 16 | M1-8 | 20 | 12 | 4 |

| 18″(DN450) | 578 | 16 | M1 1/8-7 | 20 | 12 | 4 |

| 20″(DN500) | 635 | 20 | M1 1/8-7 | 24 | 16 | 4 |

| 22″(DN550) | 692 | 20 | M1 1/4-7 | 24 | 16 | 4 |

| 24″(DN600) | 750 | 20 | M1 1/4-7 | 27 | 16 | 4 |